This one is for the electrical engineers, contractors and developers: Are you finding yourself working on bigger and bigger EV projects? Have you encountered the same challenge we have heard from many of our electrical design partners?: “We can’t get enough power service from the utility to serve the number of vehicles and chargers the customer wants.”

Traditional Load Calculations for EV Project Sites

Any electrical site designer worth their salt can do a load calculation on the back of a napkin. Assume 1 Power Factor, sum up the loads, apply a demand factor if necessary and then do the 80% rule - or as I like to think of it - add a safety factor of 25% because the site’s probably using thermomagnetic breakers.

However, technology has changed, there are new codes in the book and interconnection capacity is harder than ever to come by. So, how are you going to get that project approved and installed?

The Technical Guide For EV Fleet Charging

Load Calculations with ALM for EVSE Sites

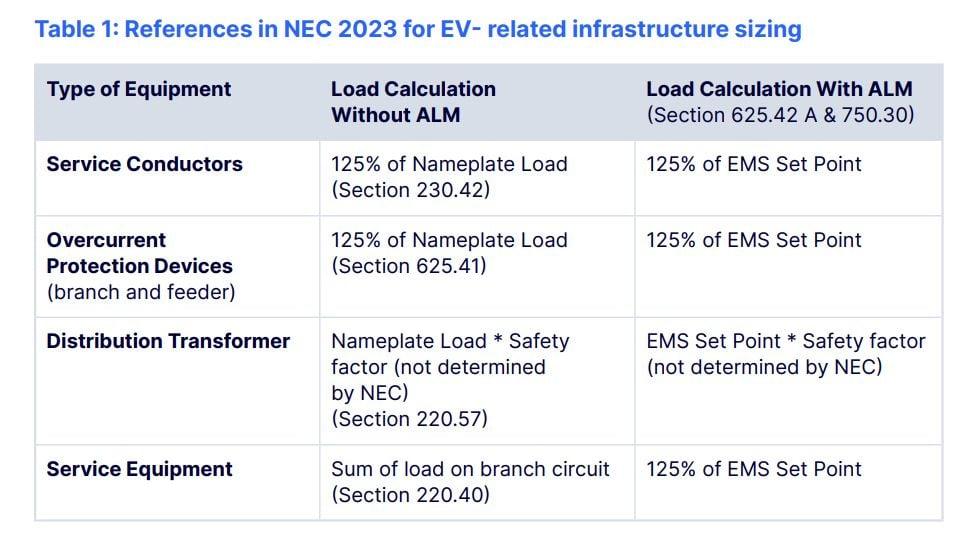

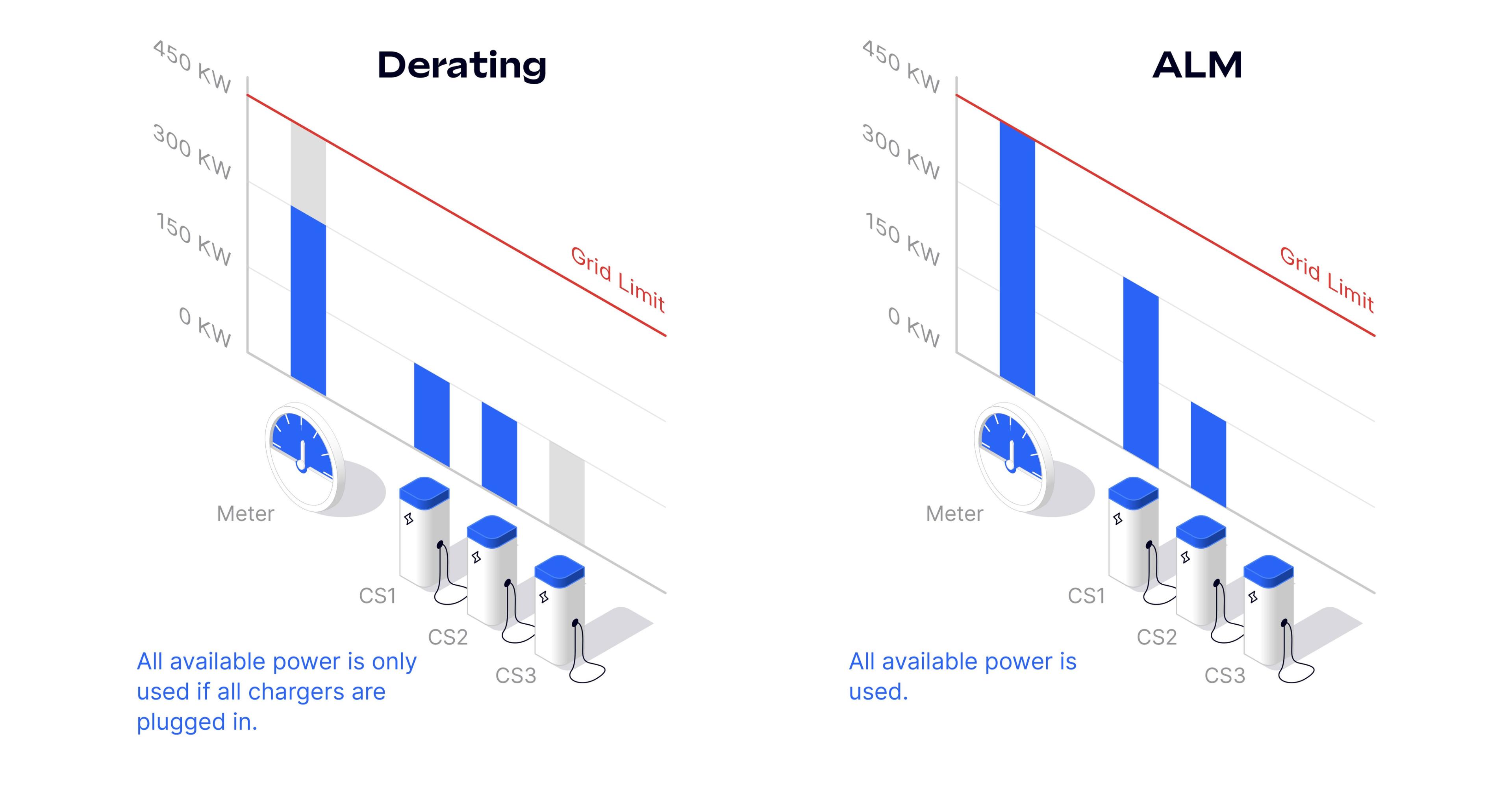

I suggest visiting Article 625.42 in the National Electrical Code). The world is getting smarter, our devices are more advanced than ever, and it's time we applied these trends to site design. Enter automated load management (ALM). If you want a full in-depth walkthrough of the technology, you can download our free ALM Technical Guide. But if math is more your thing, I’ll give you the short answer. It changes the equation we use to calculate max load and size on-site electrical equipment.

If we revisit our ‘back of the napkin’ calculation, everything stays the same except instead of summing up the EVSE loads, we install an ALM-capable charge management system (CMS), give it a threshold of power, called an EMS Set Point, and then use that limit as the “sum” in our equations. For anyone not familiar with the 2023 NEC, they have also gotten rid of the demand factor for EVSEs in residential applications – see NEC article 220.53.

How does ALM help us?

Integrating ALM into EV site planning means we now have a max load set point to use to size grid equipment. Consider these three scenarios, which demonstrate the different ways that ALM can help:

-

The utility says I can get the upgrade I want but it will take two years. My

customer’s chargers need to be installed ASAP, before their funding

expires.

Solution: Use an ALM-capable CMS as a bridging technology, install all your chargers now, and use ALM to limit the max load below the set point, set at existing capacity. When the upgrade comes through, the set point can be adjusted upward to allow your customers to charge at full capacity, or install more. -

My customer has just upgraded their interconnection, paving the way for the

next phase of their electrification journey. However, now the goal posts

have moved and they want to increase the size of their electric fleet more

than expected for the first upgrade.

Solution: Reduce the size of the next upgrade you need using ALM or even possibly prolong the needed upgrade to a future stage. -

My customer’s max load is close to the limit on their transformer, but

those loads don’t run often.

Solution: Use an ALM-capable CMS, to use that extra power when those loads don’t run, and avoid the need for a transformer upgrade.

ALM can be used to design more EVSE capacity into a site that would appear limited by grid connection. If this applies to your work, please reach out. We’re happy to share how we have used ALM-capable charge management technology on over 1,200 sites worldwide.